Metals are not used in their as-cast condition for safety-critical aircraft structures or load-bearing jet engine components. The use of cast metal in the primary structures of commercial airliners is virtually nonexistent, and it is used sparingly in military aircraft. Cast metals are used in a small number of nonstructural components on aircraft and helicopters, but not in heavily loaded structures which require high strength and toughness. The mechanical properties of cast metals are not good enough for them to be used in aircraft structures without incurring a significant weight penalty. Instead, metals are processed after casting by plastic-forming operations which increase the strength properties. Materials processed in this way are called wrought metals.

Wrought metals used in aircraft structures are produced using various processes, with the most common being forging, extrusion, rolling and sheet forming. Other processes used by the aerospace industry are superplastic forming and hot isostatic pressing. Common to all wrought processes is the plastic deformation of the metal which increases strength while simultaneously changing the shape. Most forming processes are designed to simultaneously harden and deform the metal into a simple shape, such as a sheet, plate or bar, which is then heat-treated and machined into the final component. The plastic forming of wrought metal increases the mechanical properties (except creep resistance) by the strengthening mechanisms of work hardening, grain refinement, elimination of casting defects (such as porosity), and the breakdown of alloy segregation in the casting. The forming processes used to fabricate wrought metals are a major operation in aircraft manufacturing.

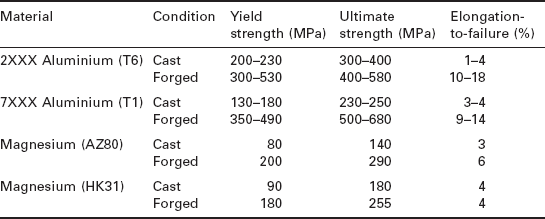

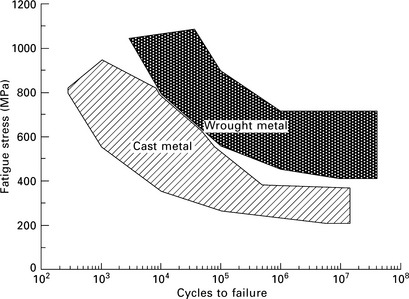

The superior properties of wrought metals over as-cast metals are shown in Table 7.1 and Fig. 7.1. The yield strength of a wrought metal is typically 50–200% higher than the cast metal with the same alloy composition. Other material properties important for aircraft structures, such as fatigue life and fracture toughness, are also higher for wrought metals. The mechanical properties are not only better for wrought metals, but their properties also tend to be more consistent through a component than as-cast metal. The properties in cast metal components are more variable because of regional differences in grain structure and segregation of alloying elements. Also, porosity is more likely to be higher in cast metals because casting pores are eliminated in the forming operations used to produce wrought metals. Wrought metal is the material of choice over cast metal in aircraft structures and engines owing to higher and more consistent mechanical properties and fewer casting defects.

Table 7.1

Comparison of typical properties for cast and forged aluminium and magnesium alloys

7.1 Comparison of the fatigue properties of cast and wrought titanium alloy (Ti–6Al–4 V).

We study the main forming processes used by the aerospace industry to produce wrought metals for aircraft structures and jet engine components. The changes to the metallurgical and mechanical properties of metals during the forming operations, including cold and hot working, are examined. Following this, the processes used for machining and drilling the wrought metal into the finished aerospace component are described.

Leave a Reply