Most cost data that are available for making a preliminary or predesign estimation are only valid at that time they were developed. Because prices may have changed considerably with time due to changes in economic conditions, some methods must be used for updating cost data applicable at a past date to costs that are representative of conditions at a later time. This can be done by the use of cost indices.

A cost index is a ratio of the cost of an item or equipment group at a specific time to the cost of the item at some base time in the past. Indices are published by the government for labor and materials (both for retail and for wholesale). The most familiar index the Commerce Price Index provides a measure of inflation each year. In equivalent cost estimation, an equipment or process cost index is used to update equipment cost as follows:

Two indices frequently used in estimating the cost of process and air pollution control equipment are shown in Table 7.11. Brief descriptions of the Marshall‐Swift and Chemical Engineering Cost Indices are given in the Chemical Engineering journal.

EXAMPLE 7.10

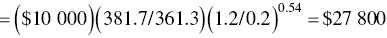

The purchase cost of a 0.2 m3 glass‐lined jacketed reactor (without drive) was $10 000 in 1991. Estimate the purchased cost of a similar 1.2 m3, glass‐lined, jacketed reactor (without drive) in 1996. Use the annual average Chemical Engineering Plant Cost Index to update the purchase cost of the reactor. The glass‐lined jacketed reactor cost vs. capacity exponent is given as 0.54.

SOLUTION

The Chemical Engineering Plant Cost Index in 1991 was 361.3 and in 1996 was 381.7 (Table 7.11). Therefore using Eq. (7.4), we get the cost of reactor in 1996

Equipment Costs

Process equipment costs can be correlated with size or capacity by the following relationship.

Table 7.11 Cost indices as annual averages.

Source: Adopted from indices published monthly by Chemical Engineering.

| Base year | Marshall‐Swift (1926 = 100) all industries | Chemical engineering plant cost index (1958 = 100) |

| 1984 | 780.4 | 322.7 |

| 1985 | 789.6 | 325.3 |

| 1986 | 797.6 | 318.4 |

| 1987 | 813.6 | 323.8 |

| 1988 | 852.0 | 342.5 |

| 1989 | 895.1 | 355.4 |

| 1990 | 915.1 | 357.6 |

| 1991 | 930.6 | 361.3 |

| 1992 | 943.1 | 358.2 |

| 1993 | 964.2 | 359.2 |

| 1994 | 993.4 | 328.1 |

| 1995 | 1027.5 | 381.1 |

| 1996 | 1039.1 | 381.7 |

| 1997 | 1056.8 | 386.5 |

| 1998 | 1061.9 | 389.5 |

| 1999 | 1068.3 | 390.6 |

| 2000 | 1080.6 | 392.6 |

| 2001 | 1093.9 | 394.3 |

| 2002 | 1104.2 | 395.6 |

| 2003 | 1123.6 | 402.0 |

| 2004 | 1178.5 | 444.2 |

| 2005 | 1244.5 | 468.2 |

| 2006 | 1302.3 | 499.6 |

| 2007 | 1373.3 | 525.4 |

| 2008 | 1449.3 | 575.4 |

| 2009 | 1486.6 | 521.9 |

| 2010 | — | 550.8 |

| 2011 | — | 585.7 |

where

- capacityB = equipment throughput, in standard units of cfm, gpm, etc.

- sizeB = equipment size, in standard units of 2 ft2, ft3, etc.

- b, b′ = constant

The exponents b and b′ vary from 0.5 to 0.8 and will average between 0.6 and 0.7 for many types of equipment. Typical exponent values for various types of air pollution control equipment are shown in Table 7.12.

EXAMPLE 7.11

A carbon‐steel cyclone designed for a throughput of 5 000 scfm was purchased in 2003 for 15 000. Estimate the cost of a 10 000 scfm carbon = steel cyclone purchased in 2007.

Table 7.12 Cost exponents for air pollution control equipment.

Source: Adopted from Peters and Timmerhaus (2002).

| Equipment type | Size range (cfm) | Cost exponent |

| Dry cyclones | 5 000–100 000 | 0.65 |

| Multi‐cyclones | 10 000–200 000 | 0.65 |

| Scrubbers | ||

| Impingement | 5 000–900 000 | 0.80 |

| Gravity spray | 5 000–200 000 | 0.62 |

| Centrifugal | 5 000–100 000 | 0.76 |

| Venture, low energy | 5 000–100 000 | 0.76 |

| Venture, high energy | 5 000–100 000 | 0.72 |

| Electrostatic | ||

| Precipitators | 10 000–1 000 000 | 0.62 |

| Reverse pulse | ||

| Filters | 1 000–100 000 | 0.62 |

| Adsorbers, fixed bed | 2 000–20 000 | 0.72 |

SOLUTION

We use the Marshall‐Swift (M‐S) equipment cost index from Table 7.11 to extrapolate the cost of a 5000 scfm unit to 2007. We find the cost exponent for cyclones in Table 7.12.

- M‐S index in 2003 = 1123.6

- M‐S index in 2007 = 1373.3

- Cost exponent = 0.65; using the Eq. (7.5), we get

- Cost10 000 scfm, 2007 = $15 000(10 000/5 000)0.65 (1 373.3/1 123.6) = $28 768 = $28 800 (or possibly $29 000. Using the Chemical Engineering Index results in an estimate of $31 000.)

EXAMPLE 7.12

Given that a wet scrubber had a total installed capital cost (TIC) of $800 000 in 2001, estimate the 2008 TIC using the two cost indices presented in Table 7.11. Use a reasonable method to estimate the TIC in the year 2013.

SOLUTION

- M ‐ S2001 = 1093.9; M ‐ S2008 = 1449.3

Assume inflation = 2.5%

Assume inflation = 2.5%

- CE2001 = 394.3; CE2008 = 575.4

Assume inflation = 2.5%

TIC2008 = TIC2001(1.0 + 0.025)5 = $1 320 845, rounded to $1 321 000

Leave a Reply